|

C = carcinogen M = mutagen R = toxic to reproduction D = developmental toxicant E = endocrine disruptor AT = acute toxicity to humans ST = systemic toxicity to humans N = toxic to nervous system SnS = skin sensitizer |

SnR = respiratory sensitizer IrS = skin irritant IrE = eye irritant AA = acute aquatic toxicity CA = chronic aquatic toxicity P = persistence in the environment B = bioaccumulation Rx = reactive F = flammability |

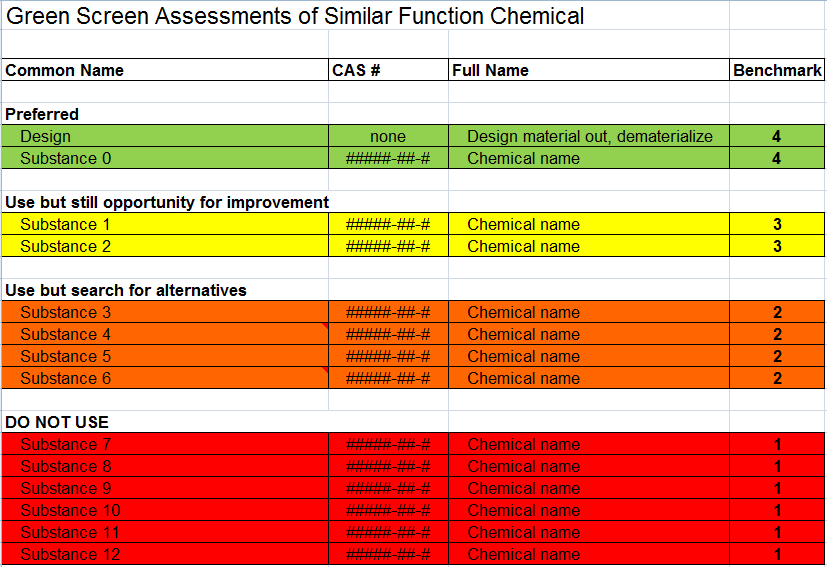

After the chemical hazard assessment is done and the table filled in, a chemical will fall into one of four GreenScreen benchmarks – unless it lacks too much information in which case it becomes a Benchmark U (Undetermined). Establishing a chemical’s benchmark is described in the open and transparent GreenScreen method documents, all of which are available online.

Hewlett-Packard instructs their suppliers to screen their chemical ingredients and reformulate to meet Benchmark 2 criteria or higher.

Most companies establish a Restricted Substances List of chemicals which they give to their supplier but this does not assure informed substitution with alternatives that are transparently safer. The danger is that formulators simply could use another chemical that is not listed but that has similar hazards leading to a ‘regrettable substitution.’ When Hewlett-Packard began using GreenScreen in 2007, they wished to remove chemicals and materials that were likely to be regulated in future as well as improve the chemical footprint of their materials. But they also wanted to ensure that any replacements did not have the same hazard profiles as the materials they targeted for substitution. HP conducted GreenScreen trainings with their suppliers to gain feedback and to help their suppliers meet the new HP procurement specifications that materials must now meet Benchmark 2 or higher. Engineers and formulators appreciate the clarity of what is being asked of them and this is now creating innovation in materials design. Many PVC-free polymers that meet Benchmark 2 or higher have now been approved and HP has extended this practice to flame retardants and all resins.

“The more you know about what you are putting into your products, the more likely you are to make better choices in product development” - Jonathan Plisco, PolyOne – supplier to HP

So what about Confidential Business Information?

The lack of chemical ingredient disclosure from their suppliers is an ongoing problem for downstream users of chemicals, particularly product designers and brands. Often suppliers do not want to disclose their chemical ingredients or they themselves simply do not have this information from their tier 2 suppliers. This leaves companies with insufficient assurance that their chemical ingredients are safe for human health and the environment. Some companies deal with this problem of disclosure and assurance of safety by relying on third party eco-labels and eco-certifications such as Cradle to Cradle (C2C) certification to promote the safety of chemicals in their products. However no eco label or certification will be as transparent as a GreenScreen assessment. In the case of a C2C assessment, there is no open disclosure of a chemical’s hazard or its data gaps. Only the C2C assessors see the ingredients and know the chemical hazards; they then look at the exposure potential of hazardous chemicals and use a criteria to classify the outcome of a chemical score. C2C gives information about their chemical scoring online but they do not reveal all their criteria for decision making. Other chemical assessment schemes, such as Target’s Sustainable Product Standard, do not disclose their exact scoring methodology.

The value of GreenScreen is that it provides full transparency of ingredient information and to meet demand, we are building a repository of assessments online. Our 2014 report on GreenScreen assessments of Triclosan and Triclocarban demonstrates how a full hazard assessment can allow regulators and companies to make informed decisions. However suppliers may not wish to give full disclosure of their chemical ingredients so buyers and suppliers can enter into a Non Disclosure Agreement to keep these CAS numbers confidential. This still allows buyers to request a complete GreenScreen hazard table from their suppliers -- with redacted chemical CAS numbers.

Recently the US Green Building Council introduced credits for both material disclosure and optimization and GreenScreen assessments can now be used for credits toward LEED certification. Architects who wish to know if the products they choose are free of GreenScreen Benchmark 1 chemicals can give preference to suppliers who meet this credit.

Before we benchmark: Is the chemical necessary at all?

Sustainability is big picture thinking and leading companies are now asking if the problematic chemical’s function is needed in a product at all. Although theGreenScreen Benchmarks 2 and 3 advocate ‘use’ while searching for safer substitutes, this does not mean GreenScreen necessarily and literally recommends that a Benchmark 2 or 3 chemical should be used. For example when we screened triclocarban, a chemical similar to triclosan, it scored a comparatively better Benchmark 2 in relation to Triclosan which scored a Benchmark 1. However both these biocides used in personal care products and soaps are highly hazardous in the aquatic environment and deemed unnecessary according to both the American and Canadian Medical Associations. In this case CPA and allies recommended that regulators and retailers avoid the use of triclosan and triclocarban altogether and assess alternatives if biocides are shown to be necessary in specific applications. Similarly, retailers and furnishing manufacturers are phasing out the use of flame retardant chemicals due to new California flammability standard, which is helping to move the market to non chemical flame retardancy.

Sustainability is a multi-faceted goal. The GreenScreen for Safer Chemicals can help companies achieve a clear understanding of their chemicals impact against 18 environmental and human health endpoints, including the amount of data gaps associated with that chemical. Companies that hold comprehensive information about the chemicals in their products, can then make informed decisions and confirm the ongoing use of their chemical ingredients or the need to find safer substitutes. GreenScreen results also facilitate informed and easy dialogue with a company’s supply chain and GreenScreen benchmark requirements can be built into a buyer’s procurement specifications, as practiced by Hewlett Packard.

For more information please contact Bev@cleanproduction.org and visit http://www.greenscreenchemicals.org/